Quality Recommended Honest Service

Traditional Values with a high tech twist

Sickamps

Sickamps Sickamps

SickampsTraditional Values with a high tech twist

Sickamps

Sickamps Sickamps

SickampsSickamps is a specialist independent and well established musical electronics repair workshop located in Harlow. We cater for musicians from Cambridge to Croydon, and Southend to Oxford. With easy transport links via train and car we are well positioned and look after some of the worlds most prestigious and highly rated amplifiers and pianos. We also have many visits from musicians from Central and Greater London due to our workshop being outside ULEZ, and congestion zone and has free parking. Trusted by manufacturers and musicians alike we off transparent and clear reports of work carried out backed by a 2 month warranty.

Our mission is simple, reduce electronic waste by repairing to component level where possible and providing solid reliable repairs ready to the toughest tour.

Over the years we’ve found our niche and is fairly defined, supported by our followers who have used and entrusted us for years with their equipment.

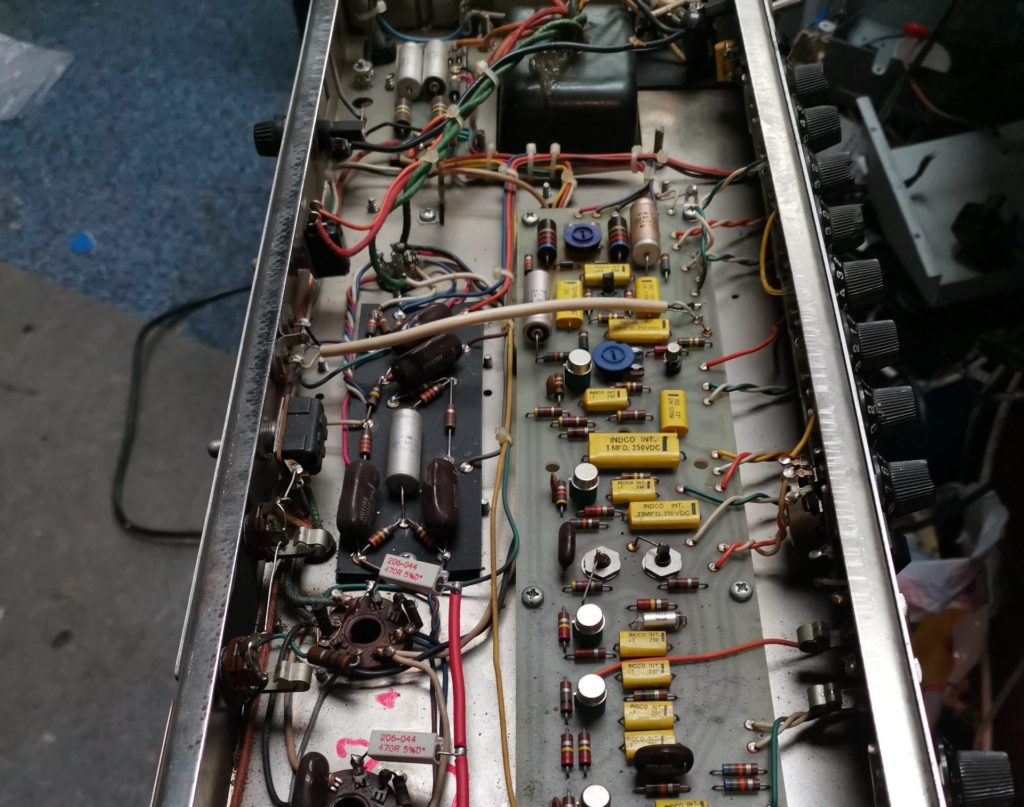

With many success of reviving older vintage synths and production pianos we carry a large stock of Yamaha parts. We also service many Korg and Casio pianos. Vintage equipment has also included old drum machines, sequencers such as the Korg NS10 where we have the skill and parts to remedy the older analogue circuits. We have vast arrays of schematics and service documents and limited spares of vintage synth parts.

We cover most commercially made valve and solid state amps and the majority of hand built and custom higher end brands, Badcat, Fuchs, Bartel, Two Rock, Friedman, Carr, Cornell, Mesa / Boogie

We have great relationships with most of the boutique builders and are one of only a few companies left who take on the more complicated Mesa repairs, things like the Triaxis rack unit, and some of the more complicated amps such as the MK V. We’re also one of few UK warranty centers for Badcat, and also look after a few high end music shops who sell high end amplifiers.

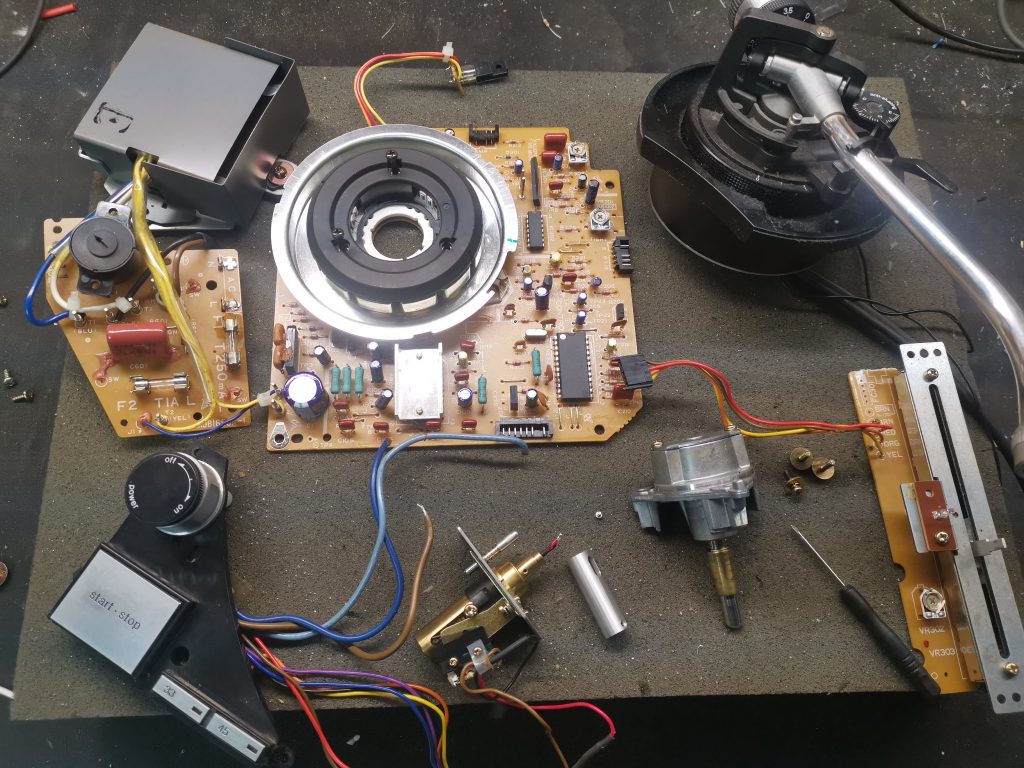

From the success of repairing many vintage equipment and frankly preferring the quality and ability to repair older equipment we have found a market after our own heart, supporting many drum and bass artists, bedroom DJ’s and northern soul wedding DJ’s we repair and service Technics decks of all varying ages and conditions. Most have the same story of being in the loft for 20 odd years having had a family and they found them recently and have got back into vinyl.

Fair to say they're not the cheapest out there,

but it stays fixed and you know they've missed nothing!

Many companies sell you their wares of “we do everything” or your “one stop shop”. We’re not. Quite simply we’re not an everything repairer, and for good reasons, we’re not afraid to turn down repairs we don’t think are suitable for us to look at.

This saves the time wasted and disappointment by both you and us that we’re unable to repair something because we cannot guarantee a great service or value by promising to repair something we might not get 100% right. We get phone calls all the time where companies take months, and yet still are unable to repair equipment where they initially say yes yes yes.

We’re honest and genuine when it comes to repairs. It takes a lot to turn down business, but that reinforces our honest nature and approach. We want to give you a great experience and build a lasting relationship.

A small local company you can trust and feel safe to recommend knowing that we will give our best. Our reviews are a snippet of other people’s experiences. Our selling point aside from this website is that we don’t take out any additional advertising, paid for promotions or sponsored listings.

We don’t buy our way to being a business, we’re a genuine reliable solution for musicians built on recommendation.

Sickamps was set up many years ago. For two reasons. Firstly because Chris the main repairer is a passionate electronics person who has a background in sound, live events and event management, and secondly he was saddened by the amount of waste electronic equipment going to landfill, not recycled or companies not genuinely being interested about the environmental impact electronics has in modern society.

Realistically very little of low grade PCB circuit boards get properly recycled for their metals, the process to strip metals is toxic, expensive and requires a huge amount of resources, power and heat to achieve and for many recycling plants they’re just not interested as the cost is greater to salvage than to mine fresh.

When considering a typical circuit board that goes wrong, it’s not just the circuit board, it’s the plastic and wood enclosure, the foam and plastic buttons and decoration that then becomes waste. Imagine the fault was caused by just a tea spoon’s worth of components. Suddenly we go from multiple wasted materials non recyclable and going to landfill. The further purchase of another piece of equipment and more future waste. Instead an example of a 1970’s amplifier, repaired with about 4 components, the owner hasn’t needed to buy another amplifier for some 50 years, kept near zero landfill apart from about a sugar cube volume of electronics.

When we buy spares we buy in bulk to reduce wasted courier journeys for parts delivery, use quality parts which provide better life before needing to be replaced and operate with local organisations for recycling and spares.

You can read more about our approach to recycling, reducing and reusing as well as the pitfalls of the disposable society and buying cheap

Based less than 3 miles from the Herts & Essex border in Harlow, Sickamps is perfectly located for easy access. With great intersecting roads and transport links including A414, A10, M11, Greater Abellio high speed London train you can be with us from Central London in 20 minutes, St Albans and Chelmsford in 40 minutes, Colchester, Cambridge and Luton in under an hour!

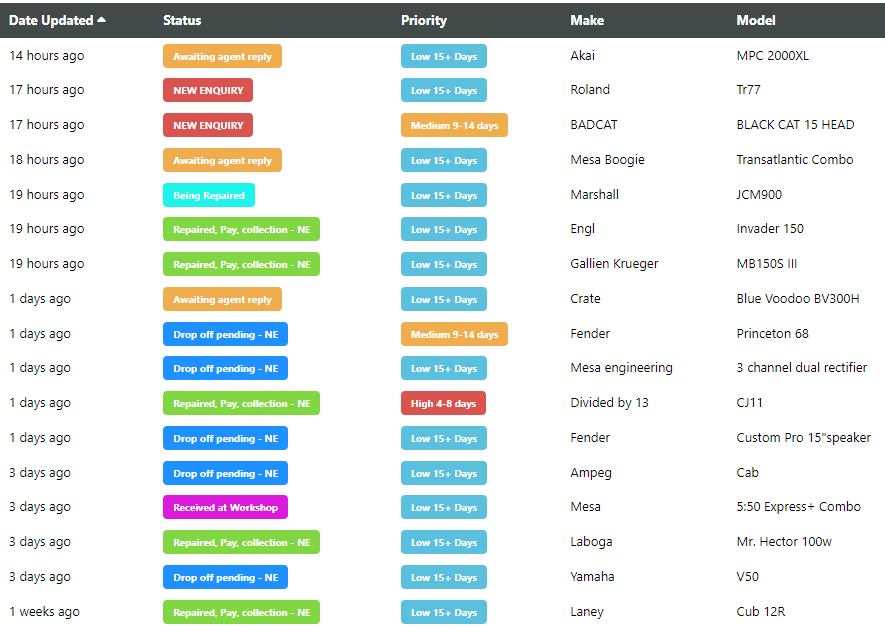

Some people may see a ticketing system as a cold fronted non caring customer interface used by large organisations to get lost in.

As a small business and in an effort to keep up with demand, we use a ticketing system. Our difference is that we use it as a tool to help speed up repairs and keep you informed at all times! The result, faster, better value and clear precise information at every step!

Communication is key

At every step you’ll get updated with an email or online ticket, from dropping off your amp, to when it’s on the bench, if we’re waiting for parts and to let you know it’s repaired.

We like visuals and the picture to the right is a typical day for us, much like a traffic light system we can easily see what is outstanding, what needs doing. Not only do we see the overall state, but you can too for your individual repair!

What does this mean for customer service?

As long as we have the parts and spares on the shelf we can generally repair most equipment within a week. If we can’t repair it you’ll know straight away that we’ve ordered parts or awaiting for manufacturer advice.

Guitar amplifier repair in Harlow, covering all of Essex and Hertfordshire as far across as St Albans, and the main towns of Stevenage, Letchworth and Royston. Electric piano repairs from Cambridge through Bishop’s Stortford, right the way down to Romford and across to Braintree. Musical stage electronic electronics repair for smaller towns Hitchin, Buntingford, Ongar, Welwyn Garden city, and closer into London including the London borough of Enfield

Prices on this website are given as a guide to assist you to budget, they are no to be taken as exact.